Testing Laboratory

State-of-the-art equipment, precision results.

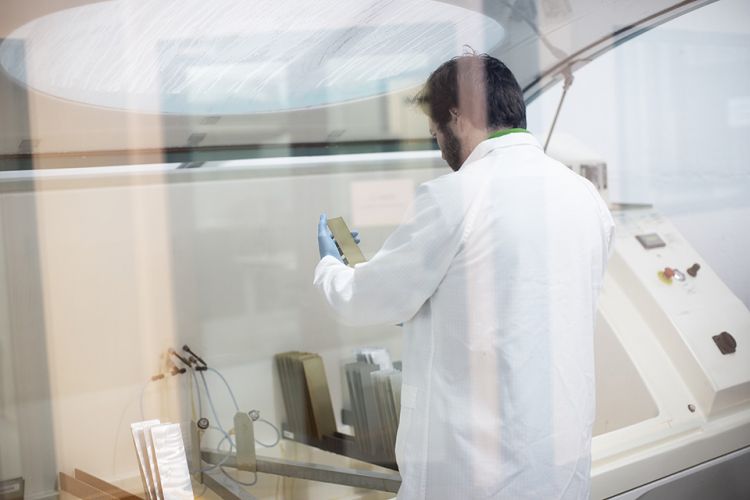

Canagrosa testing laboratories, accredited by NADCAP and ENAC in the ISO/IEC 17.025, and categorized by Airbus Defence & Space as an independent reference laboratory, covers the broadest and most demanding spectrum of physical-chemical tests for the quality control of industrial processes, including sampling and certification testing of personnel and facilities.

Canagrosa's facilities are equipped with the latest generation of analytical equipment to guarantee the highest precision and accuracy of its results, with highly qualified personnel to provide outstanding solutions to the analytical needs of its clients.

ENAC 337/LE1870 SCOPE

Control of processes, products and facilities

Canagrosa is specialised in carrying out periodic controls and tests on parts and panels programmed to verify the efficiency of the industrial process applied, offering integral management that includes the planning of the tests in accordance with the applicable regulations and the sampling by specialised personnel.

Comprehensive management for analysis and sampling by specialised personnel for chemical processes.

Planning and evaluation of periodic test of chemical process installations.

Analysis of chemical surface treatment baths and rinsing water.

Evaluation of results and trends according to the standards of the main OEMs.

- Cleaning, rinsing water and deionized water systems.

- Attack and embrittlement of tanks solutions: etch rate, intergranular corrosion and grain pitting, hydrogen absorption in titanium and alloys (pick up), hydrogen embrittlement by sustained load test and hydrogen embrittlement test in tank solutions (BPPM).

- Crack inspection process solutions: penetrant fluids and magnetic particle inspection fluids.

- Cutting fluids (drilling fluids).

Customised chemical testing or control for a given process.

Tests on processed parts and specimens to determine the physical and mechanical characteristics of the material and its reaction to controlled conditions.

- Hydrogen embrittlement.

- Tests on metallic, non-metallic and organic coatings.

- Infrared FTIR

- Abrasion resistance tests.

- Control and certification of industrial processes.

- Fixing of spherical bearings, installation of drills, ...

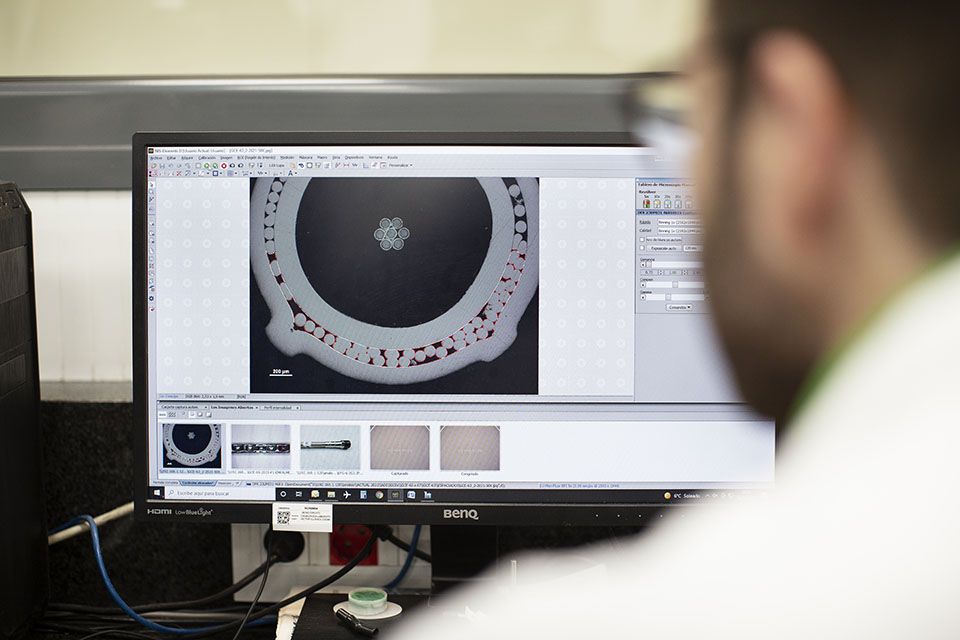

- Customised metallographic inspections.

- Periodic tests for the chemical processes control.

- Characterisation of materials.

- Evaluation of seam weldings.

- Evaluation of welds on blades.

- Tests for process control in painting operations on metallic and composite materials.

- Control and certification of facilities and technical personnel in painting processes.

- Evaluation of sealant application.

- Quality control of sealants for automatic mixings or sealant mixings made with semkits.

- Tests on adhesives for hardness, peeling, lap shear and resistance to temperature, humidity and chemical agents.

- Control of airborne particles.

- Temperature - Pressure - Humidity.

- Intergranular oxidation tests.

- Eutectic melting point.

- Plating diffusion.

- Electrical conductivity and hardness.

- Tensile strength.

- Macro and micrographic inspection of crimps.

- Contrast tests.

- Tensile tests.

Environmental tests

Controlled environmental conditions tests are used to evaluate the behaviour of materials and their treatments under standardised and extreme climatic and corrosion conditions. CANAGROSAa has the capability to carry out cyclic, continuous and ageing controlled conditions tests, designing and optimising the applied parameters according to our client’s needs.

On site testing

Mobile sampling units and mobile laboratory to cover the widest range of ON SITE services in the industrial sector.

The mobile laboratory is specially designed to operate at client facilities that require quality certification tests at a critical location and time, such as assembly line, flight line and/or after-sales.

-

Sampling on flight line and client facilities.

-

Aircraft Testing: Paints / Sealants / Hydraulic Oils, Fuels and Engine Lubricanting Oils.

-

Chemical conversion coating repairs, plating and repassivation.

Incoming testing

We provide an integral service of incoming testing of materials, optimising the client's resources and guaranteeing the process until the end of the useful life of the materials. We carry out TESTS of:

-

Paints

-

Sealants

-

Adhesives

-

Silicones

-

Lubricating oils, hydraulic oils and fuels

-

Metallic raw materials

-

Screws and standards

-

IR-FTIR

Our certificates and accreditations

The excellence and quality of the services provided by Canagrosa are guaranteed by the most demanding certifications and accreditations in the industrial sector, as well as by the specific approvals of the major aeronautical companies.

Latest News

Contact us

If you are interested in our solutions or would like more specific information about our adaptability to your needs.